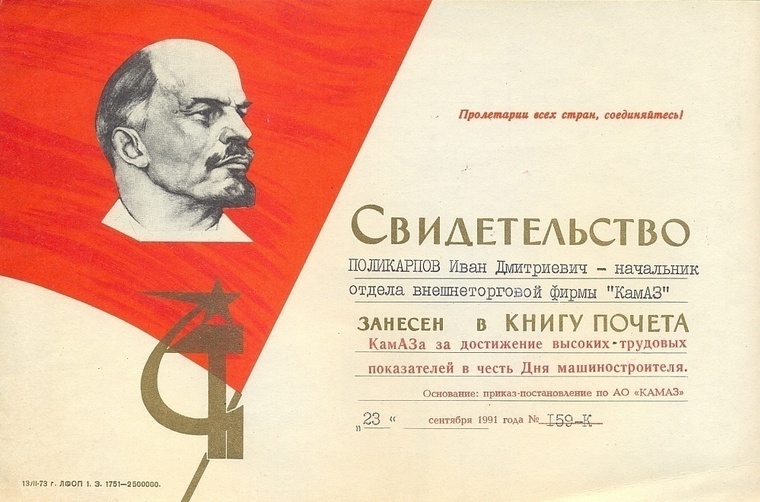

Good afternoon, Comte! Now we often hear from the experts that our country of the gas station itself can not. I propose to get acquainted with the memoirs of Ivan Dmitrievich Polikarpov (translator, n | About the years of work on KamAZ (1973-2008) | Author of Stranger. More articles of the author to read on the site.

About the years of work at Kamaz (1973-2008)

Good afternoon, Comte! Now we often hear from the experts that our country of the gas station itself can not. I propose to get acquainted with the memoirs of Ivan Dmitrievich Polikarpov (translator, later the head of the department of technical transfer of the external relations of KamAZ), and to imagine that all this applies not to history, but to any enterprise that is currently being created. What do you think, what comments would be about this hypothetical enterprise?

Ivan Dmitrievich Polikarpov on the left

Ivan Dmitrievich Polikarpov on the left

“For the first time, I learned about the plans for the construction of a complex of factories for the production of heavy vehicles on the territory of the Republic of Tatarstan from the media in 1969, being in military service in the ranks of the GSVG in the territory of the former GDR.

I was called up for military service by the military enlistment office of the city of Leninogorsk TASSR.

And there was also information that it is planned to attract firms of a number of countries from around the world to the supply of technological equipment to the plants of the future complex, including the company from Germany and the GDR.

I then thought that I could be useful there as a specialist who knows German.

Having returned after military service in October 1971 to the city of Leninogorsk, he began working in a city of schools in the city and English.

And in March 1972, for the first time, he specially arrived in the city of Naberezhnye Chelny to find out about the possibilities of employment in KAMAZ.

In the department of personnel of the General Directorate, which was located in a trailer in the village of hydroelectric power station (in the area of the current city museum), I was informed that there was no work as a translator yet, but they offered to leave their autobiography, a preliminary employment statement and home address.

At the end of March 1973, he received an invitation to work on Kamaz.

On April of April 1973, I was already hired by the department for work with foreign specialists (Oris) of the KAMAZ General Directorate for the post of senior engineer.

At that time, the translator’s position in the staffing of the General Directorate was not at all.

By the will of fate, I was adopted by the Thirteenth Department as an employee.

The head of the department was Pesin Yakov Semenovich, who came from Ukraine.

Yakov Semenovich graduated from the Faculty of Foreign Languages of Leningrad University and perfectly spoke English and German.

Further, since 1984, he worked as assistant director of KAMAZ Beha Nikolai Ivanovich and worked with him in the same position in Elabuga at a “tractor” factory under construction, which eventually did not take place.

His deputy was Saburov Oleg Alexandrovich, a participant in the Great Patriotic War, who worked before KamAZ on the island of Kunashir in the Sakhalin Region.

Mid 1970s. Left to right: 1. Pozdnyakov Sergey Nikolaevich – director of UVS KAMAZ 2. Pesin Yakov Semyonovich – head of technical translation department 3. Melnikov Nikolay Georgievich – director of the hotel in house 1/064. …5. … 6. Saburov Oleg Alexandrovich – Deputy Director of UVS 7. ….

Mid 1970s. Left to right: 1. Pozdnyakov Sergey Nikolaevich – director of UVS KAMAZ 2. Pesin Yakov Semyonovich – head of technical translation department 3. Melnikov Nikolay Georgievich – director of the hotel in house 1/064. …5. … 6. Saburov Oleg Alexandrovich – Deputy Director of UVS 7. ….

The department was located on the fourth floor of the General Directorate at the HPP.

The department already had translators of English, German, French and Italian, as well as engineers for the organization of installation supervision of foreign specialists.

By this time, on the site between the first road and the building of the open-air engine plant under construction, mountains of huge boxes of imported equipment had already been stored.

This was explained, in my opinion, by the backlog of construction work and the absence of any storage facilities.

Storage of expensive imported equipment in the open air later caused a lot of trouble for our engineers during the period of its supervised installation, due to the fact that part of the equipment was covered with rust in places, electronics without “feeding” from electric batteries simply “fell asleep”.

The construction of not only factory buildings, but also domestic facilities lagged behind.

I mean hotels for foreign specialists and restaurants for organizing their meals and evening entertainment.

The consequence of this was that the first foreign specialists had to be taken daily to a hotel in the city of Nizhnekamsk, and lunch was brought to the specialist’s workplace from the restaurant of the Kama Hotel, located on today’s Gidrostroiteley Street.

The first foreign specialist at KamAZ was the Italian Giorgio Colpo, who arrived in June 1973 to install and put into operation an outdoor compressor unit at RIZ.

An experienced specialist Danilova Lyudmila Nikolaevna, who came to us from the VAZ, worked as an interpreter with him.

She is alive and well and lives in our city.

The second foreign specialist at KamAZ was Michael Moisel, a representative of the Galvanotekhnik company from the West German city of Solingen near Dusseldorf.

He also worked at RIZ on the installation and commissioning of a galvanizing plant.

It was already the second half of 1974, and by that time the hotel in building 3/08 with the attached Rossiya restaurant was almost put into operation.

There was a small curiosity with Herr Moizel connected with his growth.

The standard beds in the hotel were 180 cm long, and Mr. Moisel was 195 cm tall, which forced the bed to be “reconstructed” and the missing centimeters added to it.

And until the commissioning of the hotel on 3/08, he was also forced to travel daily to Nizhnekamsk.

Then the mad years of mass installation of technological equipment, both domestic and imported, began.

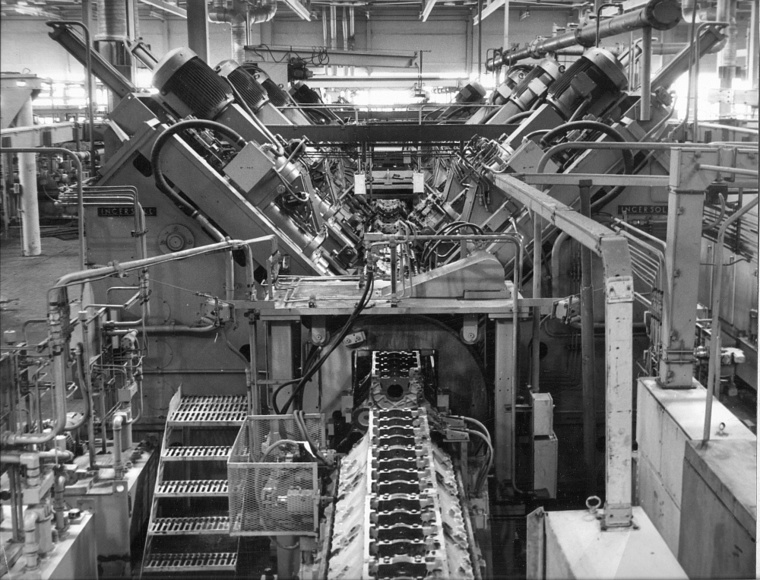

There was a chef-installation and commissioning of imported equipment at the engines factory where American specialists of Ingersol-Milling Company appeared on the automatic processing line of the engine crankcase (located at the very beginning of the factory from the new city).

Automatic line of processing of the engine of the engine of Ingersol.

Automatic line of processing of the engine of the engine of Ingersol.

Its performance is 36 blocks per hour.

This line is still in operation and processes the crankcase for repair engines.

Nearby was the installation of the sleeve processing line of another American company EXICOLO.

The West-German company Khababerzang-Tsintzen worked a little further, the equipment of which was intended for the processing of small steel details.

At the same time, the specialists of the company Morando (Italy) worked on the Makhovik processing line, specialists of the Burr company (Germany) on the line of the connecting rod, Shaudt (Germany) on the distribution shaft line.

Nearby was mounted a line of processing of the crankshaft, set by the American company …..

Further, in the direction of the blacksmith factory, the production of parts of the transmission change (checkpoint) begins.

There was the work of specialists of two large Western – German firms Liebherr Ferzantechnik GMBH and Huller – Hille GMBH with their 29 subcurricers.

KAMAZ cooperation with Liebherr continues to this day; Over the next years, she put many metalworking machines on KAMAZ, and now there is a joint work with this company to organize the production of new diesel engines.

At the same time, the chef was deployed – installation work on blacksmith, aggregate, auto -assembly, press -and -frame, foundations.

At the foundry, there were mainly equipment delivered by US firms, the PRZ was installed and launched-commissioning of unique presses from Japan, at the blacksmith factory-a line for processing the Rainstal-Technician GMBH of Germany from Germany.

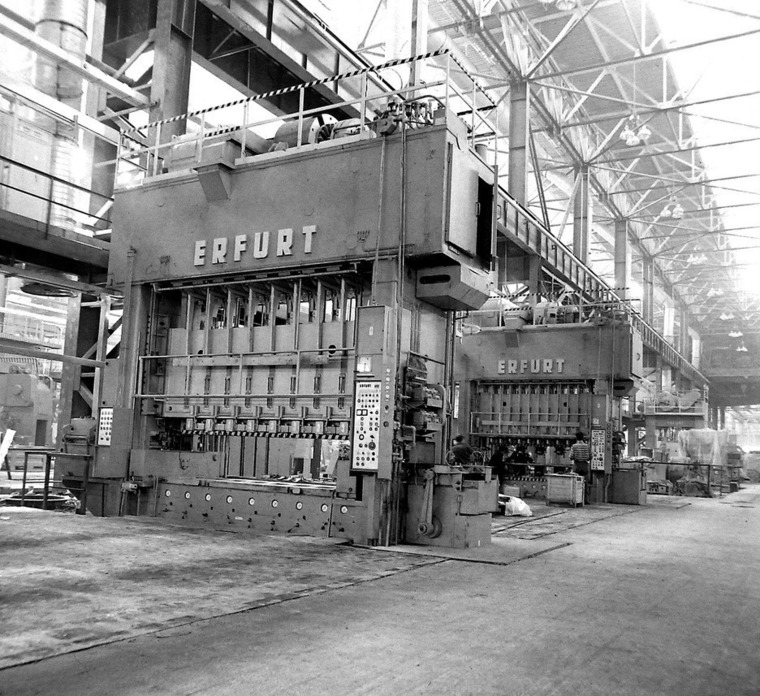

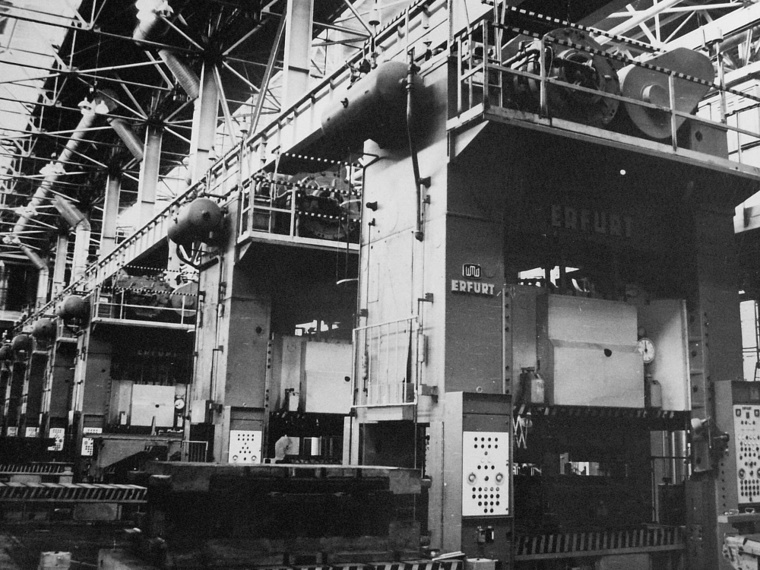

At the bottom of the photographs of cold-stamping presses with the retractable tables of Erfurt, installed at the pressing-frame plant in 1975.

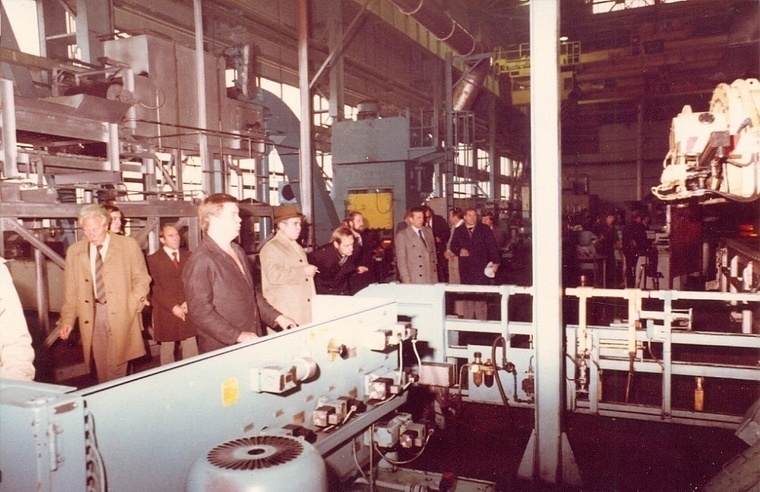

“During the years of mass installation and launching – importing imported equipment were periods when foreign specialists in the amount of more than 1000 people worked on KAMAZ.

This created certain difficulties in organizing their residence, food and transportation to factories to their jobs.

Moreover, to reduce the time for commissioning imported equipment into operation, the work of specialists was organized in two shifts.

The organization of all accommodation, organization, transportation to workplaces was engaged in the management of external KAMAZ connections.

To ensure business contacts of foreign specialists with our specialists in the technical translation department of the ATS were full -time translators of English, German, Italian, and French.

Translators who speak the languages of socialist countries also worked: Polish, Czech, Serbian – Croatian, Hungarian.

The total number of regular translators in the ATS in 1975-1977 reached 150-160 people.

Employees of the Department of Foreign Relations of KAMAZ. They sit from left to right: 1. Sinegubova Lyubov Vasilievna – Secretary of the Party Organization of the ATS 2. Nasakin Alexey Ivanovich – Director of the KamAZ UVS 3. … 4. Polikarpov Ivan Dmitrievich – Deputy Head of the Department of Technical Translation. Valentin Ivanovich Valentin Valentin-Head of the Export Spare parts 2. Sharov Dmitry Anatolyevich 3. Bibikova Galina Ivanovna-Bureau of Cultural Service 4. Stepo Franciska Innokentievna 5. Pesin Yakov Semenovich-head of the technical translation 6. Pavlova Alexandra … – Teletaypytist 7. Golubenko Anatoly Tobiashevich – Deputy Director of the ATS 8. Modina Lidia Vasilievna – Head of the Bureau Kadrov

Employees of the Department of Foreign Relations of KAMAZ. They sit from left to right: 1. Sinegubova Lyubov Vasilievna – Secretary of the Party Organization of the ATS 2. Nasakin Alexey Ivanovich – Director of the KamAZ UVS 3. … 4. Polikarpov Ivan Dmitrievich – Deputy Head of the Department of Technical Translation. Valentin Ivanovich Valentin Valentin-Head of the Export Spare parts 2. Sharov Dmitry Anatolyevich 3. Bibikova Galina Ivanovna-Bureau of Cultural Service 4. Stepo Franciska Innokentievna 5. Pesin Yakov Semenovich-head of the technical translation 6. Pavlova Alexandra … – Teletaypytist 7. Golubenko Anatoly Tobiashevich – Deputy Director of the ATS 8. Modina Lidia Vasilievna – Head of the Bureau Kadrov

In addition to permanent full-time translators, according to the Decree of the Council of Ministers of the USSR to KAMAZ for language practice, practical students were sent to faculties of foreign languages of universities from the cities of Moscow, Leningrad, Saratov, Kislovodsk, Kazan, Voronezh, Elabuga, Nizhny Novgorod, Perm, Uzhgorod.

Their stay was, as a rule, 6 months.

At the same time, their number reached 140-160 people.

In addition to them, all the plants of the Ministry of Automobile Industry of the USSR sent their full -time translators to KamAZ.

These were high -class specialists with a vase, ZIL, AZLK, MAZ and other automotive industry plants. In the end, the total number of translators reached 360 people.

Polikarpov I.D. – The third on the left.

Polikarpov I.D. – The third on the left.

It turned out that one translator worked with about 3 foreign experts.

In August 1975, the first head of the KamAZ ATS, the chief energy of the blacksmith factory Sergey Nikolaevich Poznyakov was appointed.

The management was temporarily deployed in the five -story entrance of the residential building 3/09, adjacent to the hotel 3/08.

Anatoly Tobiashevich Golubenko from the VAZ was invited by the deputy.

O.A. Saburov was approved by the deputy head of the ATS for work with personnel.

I'M WITH. Pesin continued to work as the head of the largest chief department – installation work and technical translation, where engineers and management translators were concentrated.

The tasks of the department were the work on organizing and controlling the stroke of the chef – installation work of imported equipment at all plants of the complex, drawing up a schedule for the arrival of foreigners of foreigners as it is ready for the area of factories for the installation of equipment and much more.

I will not say the exact chronology of the management of the management of the management, but about these were: Poznyakov S.N., Nasakin Aleksey Ivanovich (from the post of director of the aggregate plant), Saturday Alexei Pavlovich (director of the Kuznechny Plant), SHAROV Dmitry Anatolyevich (native brother Sharov Vyacheslav Anatolyevich, Sharov, Sharov, main (.) Riza designer), Pershko Anatoly Tikhonovich (worked in the ATS for only a few months), Vyugzhengin Vladimir Arkadievich, Galiullin Nail Fatykhovich (former secretary of the KAMAZ party committee), Anakhin Vladimir Vladimirovich and Valeev Nail Ismagilovich (came from the trade union organization of the foundry), Safin M. G. and Kevbrin I.V. You are familiar with you.

What were the difficulties? Difficulties were mainly due to the lack of sufficient places in hotels and restaurants for the organization of nutrition of specialists.

In addition to hotels in buildings 3/08, 1/06, the city temporarily provided a residential building 7/18 under their resettlement.

The city restaurant Druzhba in the 29th complex was also given to foreign specialists for lunch time, they had to have lunch in 2 shifts.

It became easier after the commissioning of the RUSSIA restaurant in the 1st complex (now the NUR Youth Center near the KAMAZ 1/06 hotel).

The hall in the restaurant Russia at the hotel in the house 3/08 1987. From left to right: 3. Polikarpov Ivan Dmitrievich – Deputy Head of the Department of Technical Translation. 5. Bournyshev Alexander Alekseevich – Deputy Director of the ATS 6. Kurushina Valentina Alekseevna – Deputy Director of KAMAZ 7.. Galina Aleksandrovna – Director of the restaurant Russia Help in the definition of people was provided by Khusnutdinov Ravil Sabirovich.

The hall in the restaurant Russia at the hotel in the house 3/08 1987. From left to right: 3. Polikarpov Ivan Dmitrievich – Deputy Head of the Department of Technical Translation. 5. Bournyshev Alexander Alekseevich – Deputy Director of the ATS 6. Kurushina Valentina Alekseevna – Deputy Director of KAMAZ 7.. Galina Aleksandrovna – Director of the restaurant Russia Help in the definition of people was provided by Khusnutdinov Ravil Sabirovich.

The ERA restaurant also worked at the 1/06 hotel.

There were certain difficulties in organizing cultural and everyday leisure of specialists. Indeed, at that time in the city practically, in addition to the Energetik DC, the Chulpan cinema, there were no cultural institutions.

It was especially difficult in winter.

In the summer, it was a little easier thanks to the Gaidar ship, which stood in the area of today's Ilychevka village in one of the Kama River Zatons, which was converted for summer holidays with the possibilities of catering and night rest.

But after blocking the Kama in the fall of 1978, we lost this opportunity. The ship Gaidar was later transferred to the balance of the trade union organization of the press andramed plant and was transported to the recreation center of this plant in Kama.

Below in the photo, the solemn evening of the leadership of the blacksmith factory with specialists from Germany. Presumably, September 1979.

From left to right: 1. … 2. Pesin Yakov Semenovich – Head of the Technical Translation Department (in a light suit) 3. Walner Ernst – the head of the installation of the Rhinstal GMBH technician, which mounted the crankshaft line at the blacksmith factory. 4. … – A representative of a German company (in a tubeler) 5. Poznyakov Sergey Nikolaevich – Director of the UVS KAMAZ Talks with Semendiy Vladimir Ivanovich – chief engineer of the blacksmith factory. 6. … – A representative of the German company (in a tubeler) 7. Valiullin Nekulla Khalitovich – Translator 8. Saturday Alexei Pavlovich – Director of the Kuznechny Plant 9. … 10. …eleven. Polikarpov Ivan Dmitrievich – ATS translator

From left to right: 1. … 2. Pesin Yakov Semenovich – Head of the Technical Translation Department (in a light suit) 3. Walner Ernst – the head of the installation of the Rhinstal GMBH technician, which mounted the crankshaft line at the blacksmith factory. 4. … – A representative of a German company (in a tubeler) 5. Poznyakov Sergey Nikolaevich – Director of the UVS KAMAZ Talks with Semendiy Vladimir Ivanovich – chief engineer of the blacksmith factory. 6. … – A representative of the German company (in a tubeler) 7. Valiullin Nekulla Khalitovich – Translator 8. Saturday Alexei Pavlovich – Director of the Kuznechny Plant 9. … 10. …eleven. Polikarpov Ivan Dmitrievich – ATS translator